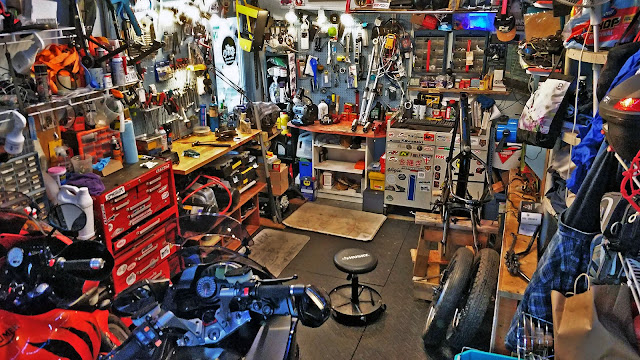

The never ending winter drones on up here, so I'm putting my back into getting the '71 Triumph Bonneville project closer to a state of mobility.

I have a new 750cc head and pistons on hand, so I gave the piston rings a go. Installing them is pretty straightforward and the first set went in no problem, but as I was compressing the second set into the cylinder sleeve it didn't feel right, so I backed everything out and the bottom ring came out in pieces. I can only think it was already compromised in the package.

I sent Britcycle an email and they looked through the warehouse to see if they had any extras laying around, but I was out of luck, so it's a $100 failure (new rings, taxes, shipping). Ouch. This got me looking at costs for this vintage project. The last one I did was the Fireblade. Those are my favourite kinds of restorations. Parts are easy to find and relatively inexpensive, the bike is rideable fairly quickly and, after riding it for a season, I can turn it over for at least what I put into it (or with a small profit as was the case with the Fireblade). |

| New cylinder heads and cylinders... and broken ring. |

I think I'm still right way up on the Bonneville simply because these older bikes seem to work under their own economy. I was looking up prices of what I've got on eBay this evening and the frickin owners manual that Bryan threw in at the last minute is $50US! A used top end is $500US (and Bryan gave me 2 of the things!). I imagine I could double my money just parting it all out, though dealing with people doing that would be a giant pain in the ass - at least it has been with the newer bike crowd, maybe the vintage types are less adversarial.

I had a couple of choices when I was considering going old school, and I think I picked the hardest possible one to bring back to life. The technical side of it doesn't bother me, but with costs increasing all around I'm bothered more about the high prices and difficulty finding and shipping parts than I am with what I've got to do to bring it back. That old BSA would have probably been a better choice for my first vintage resto, but it (and alas, Bryan) are long gone.

I've got what I've got, and I've got a lot of it, and I'm crafty. I'll see what I can do about replacing fasteners and the other bits and pieces I'm missing without it breaking the bank, those these strange old British pre-metric fasteners are a story unto themselves. The goal right now is to rebuild the bike to an operational state and then maybe ride it for a bit before putting it up for sale. I still need a seat and exhausts and I'll need other odds and ends like control cables. If I can get it back to a state of play, I think I can cover costs and move it along, then I'm thinking I'll go back to my favourite hunting grounds: forgotten bikes from the 80s, 90s and 00s that I can turn over for next to nothing while giving me a chance to ride something different for a little while.

When the ring crumbled on me I changed gears and rebuilt the Amal carbs. That went well, but I'm missing two of the bolts to put the second carb back together - they weren't on it when I wiped the mud and rust away. It's these little setbacks that stall things, and it's not like I can grab a couple of replacements out of my big tray of bolts (most of which are metric).

How simple can you make a carburettor? These old Amals are pretty close to first principles. The combination of archaeology and simple mechanics is very appealing when everything else I ride carries a computer and my day job is all about them - it's nice to be fully analog!

I'd broken down the carbs in the fall and left them packaged in a segmented toolbox. Putting them back together was problem free and the kits I got from Britcycle replaced all the gaskets and rubber grommets in them. The old rubber bits were really showing their age.

|

| Guess which one is the 50 year old ring (I;m assuming they're original)? |

|

| Just need some bolts (at $3.50US a pop) |

If money and time were no object I'd dig deeper into this vintage resto thing - I dig the mechanical simplicity and I enjoy seeing how mechanical evolution happens over time. As a hobby in retirement, it has great appeal, but I'm some years away from that much free time on my hands.

I'll see this one through and then refocus on the SPQR-WRO (small profit, quick return - with riding opportunities) side of it where the costs and time commitments aren't quite so demanding.

.gif)