I soldered a new battery into the rear temperature sensor on the Concours when I changed the back tire last year after picking up a puncture. The front was starting to get sluggish when connecting wirelessly, suggesting the battery was dying and the front tire was due a change, so I did that one in the fall. Unfortunately the sensor didn't pick up signal after reinstallation. Rather than beat up that old sensor again I started looking for alternative options.I love a good hack, and Big Red walks you through one here on how to take aftermarket tire pressure sensors, program them to your stock Kawasaki and then use them instead of expensive stock items. The coding unit is $230, but works on anything, meaning I'm not beholden to a dealer for tire pressure sensors on the cars in the future either. A pack of 2 sensors is $95, so all together a full sensor replacement on the bike including the tool needed to program them was $325. The stock sensors are $258 each, so an eye watering $516 for the pair. $200 cheaper and I have the tool that's usable across a wide range of vehicles. That's my kind of hack!

How did it go? After all the frustrations with the Tiger and Triumph, the C14 reminded me how nice it is to work on a bike that's supported by its manufacturer, riders and the aftermarket.. When I compare the thriving online communities at COG and other online forums that support Kawasaki ownership, I can only think, 'way to go team green.' By comparison I read a post on one of the Triumph forums that said, 'these forums are dead. Everyone is giving up on these old bikes..." Except the bikes in question are not that old.

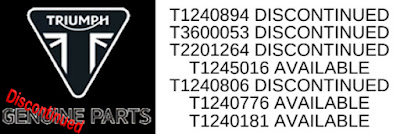

When I walked into my local Kawasaki dealer and ordered parts for my mid-nineties C10 there a few years ago there was never an issue. If I hop into an online forum for the Kwak I see an active community full of ideas and support. Most of the Hinckley Triumph forums for anything over 15 years old are derelict. The posts on them are at least five years old giving you some idea of what trying to keep an older Hinckley Triumph on the road is like (ie: impossible - the manufacture considers them disposable bikes). It makes me question owning another one, which is a real shame because I wanted to believe in the brand, but they only market their history, they don't honour it by supporting owners in keeping old Hinckley machines in motion.

Back in the land of the living, Big Red's walkthrough was spot on. I popped one side of the new front tire off the rim and removed the 14 year old sensor. I couldn't see why it wasn't getting power - my soldering looked good - maybe a bad battery? No matter, new parts are going in.

If you know Big Red's Mazda 3 2004 sensor hack matches Concours ones, then the rest is straightforward. I set the MaxiTPMS unit to the Mazda settings and then put in the ID number from the old C14 sensor. The wireless upload only took a few seconds.

I could also check the sensor once it was programmed, which gave me some piece of mind before putting it all back in the tire. Though an alternative is to set the sensor when it's installed, which is also an option (the programming unit could still see and modify the sensor in situ). This also means I can test and even reset sensors without having to pull the tire in the future!

The whole process was straightforward, aided by a warm March day where I could leave the tire in the sun while I set the sensor. Warm tires are much easier to stretch over the rim!

I installed the new sensor which fits snugly in the rim. All the parts including the tool from Autel felt like quality pieces that will last. With the tire reinflated I put the wheel back in and torqued everything to spec while also making sure everything was grease free (especially the brake bits).

I took it up the street with the intention of riding around the block because that's how long it usually takes to get the dash reading the wheel pressures, but this new sensor had it showing in seconds - before I even got a hundred yards up the road. I checked it against the digital tire pressure gauge and it's right on the money in terms of accuracy.

It felt good to have a win in the garage after banging my head against the Tiger for so long. Speaking of which, I recently attempted to plastic weld the part they won't supply any more and as I was putting it back together the wiring broke off on the fuel level unit (because I've had the tank off so many f***ing times!).

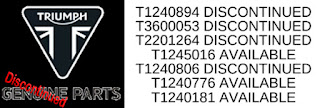

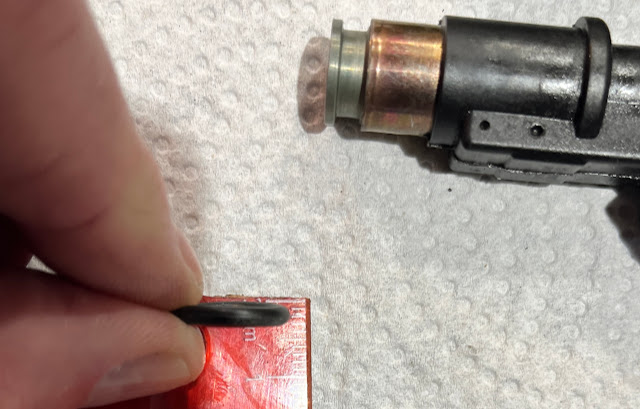

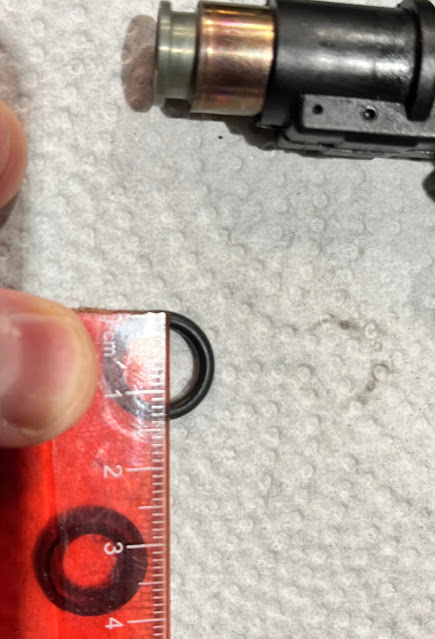

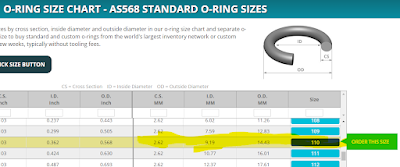

I'm so bloody minded I'm going to try and solder the wire back on even though it broke in the worst possible spot (right at the unit so there isn't much to work with). The stock unit probably isn't available and is a salty $155 even if it is. I'm doing this in part just to see if the latest attempt at keeping the old thing in motion works. The plastic welding on the idle speed control valve (which they don't even list in parts now) went well and the piece seems serviceable. I want to see if it works.

If I had more time I'd see if I could find an industrial CAD shop who could 3d scan it and then get me a file that I could use to 3d print a replacement. What would be even nicer would be if Triumph shared that CAD file with us all since they aren't bothered to produce the part anymore. With a bit of collaboration, the aftermarket could help keep older Hinckley Triumphs in motion.

As much as it pains me, I think I'm going to take Triumph's hint and let the Tiger go... which is something I never thought I'd say. So much for my goal of hitting 100k with it. |

| It is actually nuclear powered - the plutonium goes in under than panel, like on Doc Brown's DeLorean... |