Some pictures to help me put this complicated 3d puzzle back together again properly.

Friday, 18 April 2025

Saturday, 25 May 2024

Prioritizing Work and Saving My Patience for What Matters

I've sorted out '90s Fireblades and Honda never blinked when I was looking for parts. Suzuki is legendary with how they look after their engineering history, and Kawasaki has also been nothing but solid when I was working on older machines. I actually found it easier to find parts for a 53 year old Meriden Triumph than I have with much newer Hinkley machines. I've said it before and I'll say it again, for a company that markets on their history so heavily, Triumph vanishes when it comes to providing parts support, even for recent machines.

I took Chris's advice and went looking for backup used parts. This time around I found a throttle body that looked like it has spent some time in an archeological dig, and it arrived in a beaten up box but this time the seller padded it well and the plastic bits were intact. I cleaned and dismantled the unit and now have spare throttle bodies, fuel injectors and a complete idle control housing along with all the other odds and ends.

When I put the Tiger back together I tried putting pins in the broken wires on the fuel sender but it didn't work. I got a replacement fuel sender, but this time from a US eBay parts provider. I foolishly thought the shipping would be less but eBay surprised me with a surcharge on delivery that was 3x the shipping costs. Both the throttle body and the fuel sender came in on the same week. The throttle parts were much bigger and heavier and came from the UK with no surprise surcharge and the shipping cost was 30% lower. The moral here? Don't buy used parts on eBay if it's from an American based seller - you'll get caned by US Post surcharges. No so with UK suppliers.The good news is the new part works well, but not without other teething problems. That age of this bike is really starting to show. The wires had broken in the sender unit but unbeknownst to me they'd also broken on the other side of the connector, so when I first plugged the new unit in I got nothing. After taking the tape off I discovered the broken wire, cut off the connector, crimped on new plugs and it works a treat.

While I was waiting on parts I pulled the valve cover and checked the valves just to make sure they weren't what might be causing the stalling and hesitation.

Links & Pics

|

| With the Bonnie and bits gone, there is much room (both mentally and physically) to get on with keeping the Tiger in motion. The Kawasaki remains rock solid. |

|

| Used on Triumph models up until four years ago - they don't make these any more. |

|

| I'm taking the broken one to bits and measuring all the bits. I currently have two plans: 1) digitally 3d model the part and look into 3d printing options with fuel proof materials. Nylon filament printing seems to be the fuel-proof material of choice. Lots of services out there. 2) is to build my own copper/steampunk version of this plastic bit using copper piping and fittings. |

|

| My pins in the connectors attempt with the old fuel sender didn't cut it. |

|

| I thought the C14 might have an oil leak, but it turned out to be the oil in the fairing after the spring oil change. After a thorough cleaning it's running like a (oil tight) top. |

Here are some details on the voltage fixes for 955i Tigers. Running the wire from the reg/rec to the battery was straightforward:

https://tigertriple.com/forum/index.php?topic=3843.75 is lost to the internet (those Hinkley Triumph support forums are dying out).

https://www.advrider.com/f/threads/sasquatch-link-please.1267616/

https://www.advrider.com/f/threads/tiger-electrical-upgrades.496199/

Reg/Rec update:

https://www.triumphrat.net/threads/charging-system-diagnostics-rectifier-regulator-upgrade.104504/

This is the Fuel Level Sender: Part Number: T2400526 that needed a swap...

Wednesday, 13 March 2024

Going Aftermarket with Kawasaki GTR1400/C14 Tire Pressure Sensors

I love a good hack, and Big Red walks you through one here on how to take aftermarket tire pressure sensors, program them to your stock Kawasaki and then use them instead of expensive stock items. The coding unit is $230, but works on anything, meaning I'm not beholden to a dealer for tire pressure sensors on the cars in the future either. A pack of 2 sensors is $95, so all together a full sensor replacement on the bike including the tool needed to program them was $325. The stock sensors are $258 each, so an eye watering $516 for the pair. $200 cheaper and I have the tool that's usable across a wide range of vehicles. That's my kind of hack!

How did it go? After all the frustrations with the Tiger and Triumph, the C14 reminded me how nice it is to work on a bike that's supported by its manufacturer, riders and the aftermarket.. When I compare the thriving online communities at COG and other online forums that support Kawasaki ownership, I can only think, 'way to go team green.' By comparison I read a post on one of the Triumph forums that said, 'these forums are dead. Everyone is giving up on these old bikes..." Except the bikes in question are not that old.Links

Big Red's how to: https://zggtr.org/index.php?topic=25416.0

The parts you need: https://www.amazon.ca/dp/B07YYDDXXH?smid=A2S0RW9CKA3NU3&ref_=chk_typ_imgToDp&th=1

https://www.amazon.ca/dp/B09QC4T48J?psc=1&smid=A3AMY38QRT4FIZ&ref_=chk_typ_imgToDp

What not to do...

$258 each for stock: https://www.blackfootonline.ca/sensor-tpms-315mhz-21176-1179

$175 US + shipping + customs on eBay: https://www.ebay.com/itm/175070359610

|

| It is actually nuclear powered - the plutonium goes in under than panel, like on Doc Brown's DeLorean... |

Sunday, 28 January 2024

The Struggle is Real: Trying to Keep a Triumph 955i Tiger on the Road

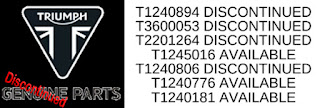

Blackfoot Motosports in Calgary's site seemed to suggest that they could provide this complex plastic piece that doesn't enjoy Canada's extreme temperature swings (I've gone through 2 of them so far). So I ordered it! Guess what:

Inevitably, the only broken piece on the damned thing was the fragile idle housing, which was cracked around the base in exactly the same place that the one I'm trying to replace is.

|

| The happy face getting the solution to my problem in (the box on the bench)... then, well, you know what happened. |

Tuesday, 17 October 2023

Finding Your Way Around OEM's Giving Up on Parts Support: Triumph 955i Fuel Injection Seals

|

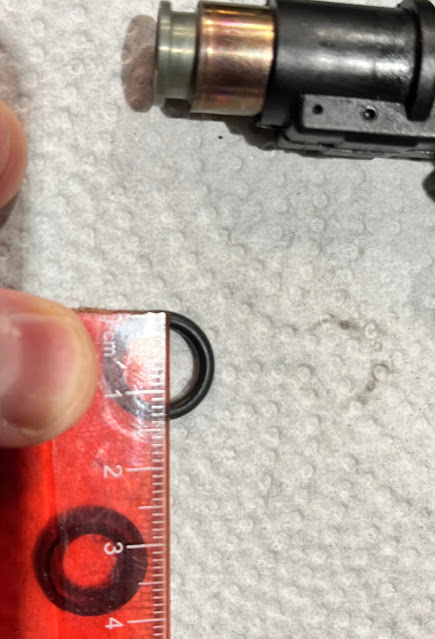

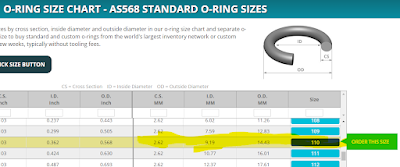

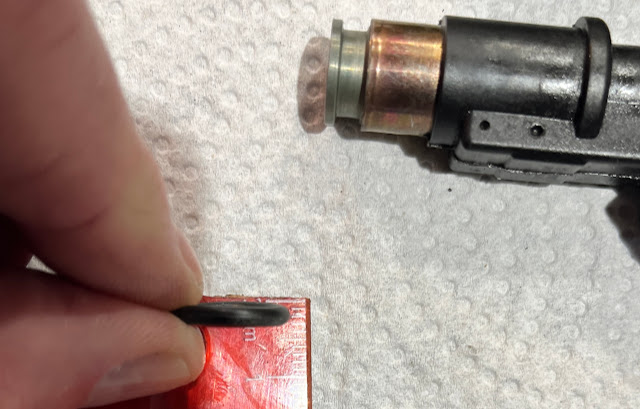

| The thick ones go on top where the fuel injector meets the rail. My best guess is 3mm thick by 1.5cm outer circumference. |

|

| The skinny ones go on the bottom where the fuel injector slides into the intake manifold. |

|

| My best guess there is 2mm wide by 1.4mm outer circumference. |

The All O-Rings site also has a good description of the materials you want to get your o-rings in. Nitrile and Viton are what I went with in the pointless Amazon order, but those are the materials you want in a fuel heavy application like this.

That's the configurator (right) - pretty straightforward, but it sounds like they manufacture each order, which probably won't make this a viable solution for someone just trying to keep their old Triumph on the road.

If only there was some kind of network of retailers who supported Triumph motorcycles who could order this parts to help their customers keep their older Triumphs rolling... some kind of 'dealer' network who understand how parts work and how to order this sort of thing in large enough quantities to make a profit while offering customers what they need.

RESOURCES

How hot motorcycle engines runs: https://blog.amsoil.com/extreme-heat-is-hard-on-your-motorcycle/Buna (Nitrile or NBR) o-rings: https://sealingdevices.com/o-rings/buna-n-o-rings/

Viton vs. Nitrile o-rings: https://www.nes-ips.com/viton-vs-nitrile-o-rings/

All O-Rings https://www.allorings.com/

They have sizing tools! https://www.allorings.com/o-ring-kits-and-accessories/o-ring-sizing-tools

I'd prefer to use All O-Rings for the parts, but they might be a B2B type of thing, and I'm not a B.

Amazon's kits: